Building furniture is a process that has been around for centuries. Though the materials and methods have changed over time, the basic steps remain the same. With advances in technology, there are now new ways to build furniture that can save you time and money. Here are seven reasons why you should invest in advanced technology for building furniture.

1. Increased efficiency

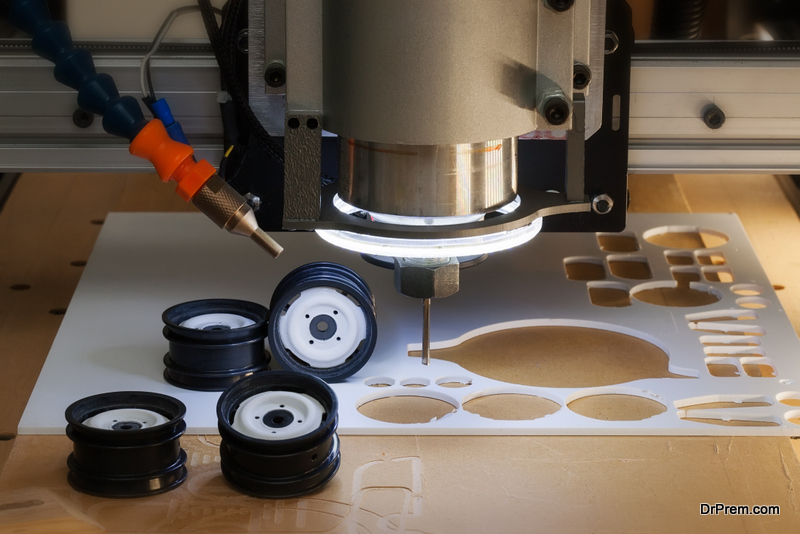

In the past, building furniture was a time-consuming and often error-prone process. But with advances in technology, you can now build furniture much more quickly and with fewer mistakes. For example, using a CNC machine to cut and shape pieces is much faster and more accurate than doing it by hand. And thanks to 3D printing, you can now create prototypes and even finished products quickly and easily. As a result, you can get your furniture project done much faster and with fewer headaches. So if you’re looking for a quicker and easier way to build furniture, take advantage of the latest technology. You’ll be glad you did.

2. Less waste

In addition to being a renewable resource, wood is also one of the most versatile building materials available. Whether it’s used for framing, flooring or furniture, wood can be cut and shaped to suit any need. And thanks to advances in technology, it’s now possible to create long-lasting joints with very little waste. This means that less wood is needed overall, which helps to conserve our forests. In addition, the use of recycled or reclaimed wood is also on the rise. By using wood that would otherwise end up in a landfill, we can further reduce our impact on the environment. From start to finish, wood is a sustainable choice for any building project.

3. More customization

With the advent of advanced technology, furniture buyers now have more choices than ever before. Thanks to new manufacturing techniques, it is possible to create pieces of furniture that are highly customized to the buyer’s specifications. This means that you can get exactly the piece of furniture you want, whether it’s a sofa in a specific color or a restaurant chairs that is the perfect size for your restaurant. With so many options available, there is no reason to settle for anything less than exactly what you want. Advanced technology has made it possible to get furniture that is both stylish and functional, so there is no excuse for settling for anything less than the perfect piece. Whether you’re looking for a new sofa or a dining table, make sure to take advantage of the customization options that are now available. You’ll be glad you did.

4. Improved quality

With the help of new machines and materials, designers and manufacturers can now create pieces that are stronger and more durable than ever before. In addition, the use of advanced technology can also improve the quality of furniture in other ways. For instance, computer-aided design (CAD) software can be used to create highly detailed and accurate plans for each piece of furniture. This ensures that every component fits together perfectly, resulting in a final product that looks and feels extremely polished. Similarly, 3D printing can be used to create prototypes of furniture designs, allowing manufacturers to perfect their plans before starting mass production. Ultimately, by investing in advanced technology, furniture makers can produce higher-quality products that will last for years to come.

5. Reduced environmental impact

The traditional way of manufacturing concrete involves mining sand and clay, which are then mixed with water and other chemicals to make a slurry. This slurry is then transported to a factory where it is poured into molds and left to harden. The manufacture of precast concrete uses a different process that is not only more efficient but also produces less pollution and uses less energy. First, the raw materials are mixed in a factory instead of at the construction site. This allows for better control of the mix, which results in a stronger and more consistent product. The mixture is then transported to the construction site and poured into molds. Once the concrete has hardened, the mold can be reused or recycled, further reducing the environmental impact of the manufacturing process. In addition, because the manufacturing process is more efficient, it requires less energy to produce precast concrete, resulting in lower emissions of greenhouse gasses. As a result, precast concrete has a reduced environmental impact compared to traditional concrete.

6. Longer lifespan for your furniture

When making a furniture purchase, most people focus on two things: style and price. However, another important factor to consider is how long the furniture will last. With proper care, advanced technology-made furniture can last for many years. Some types of furniture are designed to last a lifetime. For example, solid wood furniture can be passed down from generation to generation. Similarly, leather furniture ages gracefully and develops a unique patina over time. Furniture made with other materials, such as metals or glass, can also last for many years if properly maintained. With a little bit of care and attention, your furniture can be an integral part of your home for many years to come.

Article Submitted By Community Writer