The History and Uses of MDF in the Home

When it comes to modern interior design, MDF—short for Medium Density Fibreboard—has played a significant role since its introduction in the mid-20th century. While the name may sound technical, MDF has revolutionized the way we approach décor and furniture, offering affordable and flexible solutions for both professionals and DIY enthusiasts. Its popularity endures today as it continues to inspire creativity in home improvement projects.

What is MDF and How is It Made?

MDF is created by breaking down wood pulp into individual fibers, which are then bonded together using resin and compressed under heat and pressure. This process results in a strong, smooth material that can be produced in a variety of sizes and thicknesses. MDF’s uniform texture and durability quickly made it a superior option to traditional particleboard and plywood, while being more cost-effective than natural solid wood. Its affordability and quality led to widespread use in cabinetry, furniture, and home décor projects.

MDF’s Role in Interior Design Trends

Thanks to its adaptability, MDF became a favorite in mid-century design. It could easily be machined into complex shapes and featured a smooth surface that was ideal for painting or adding veneers. This made MDF perfect for the vibrant, sleek aesthetics of the 1960s, as well as the more earthy, rustic styles of the 1970s.

During the 1970s, wood paneling and natural textures surged in popularity. MDF adapted effortlessly to these trends, especially with its suitability for veneers. These veneers could replicate the look of real wood grain, providing a natural appearance at a fraction of the cost. This made MDF an essential material for both contemporary and traditional interior styles.

The DIY Boom and MDF’s Rise in Popularity

The 1970s also marked a rise in the do-it-yourself (DIY) culture. Homeowners embraced the idea of building, adapting, and repairing their own spaces, with MDF becoming a go-to material for these projects. This trend re-emerged in the 1990s and reached new heights during the COVID-19 pandemic, when many took on home improvement projects. The versatility of MDF, teamed with the increased availability of boards of MDF cut to size by the supplier to suit particular projects without excessive cost or waste, continues to make MDF a favorite among DIYers.

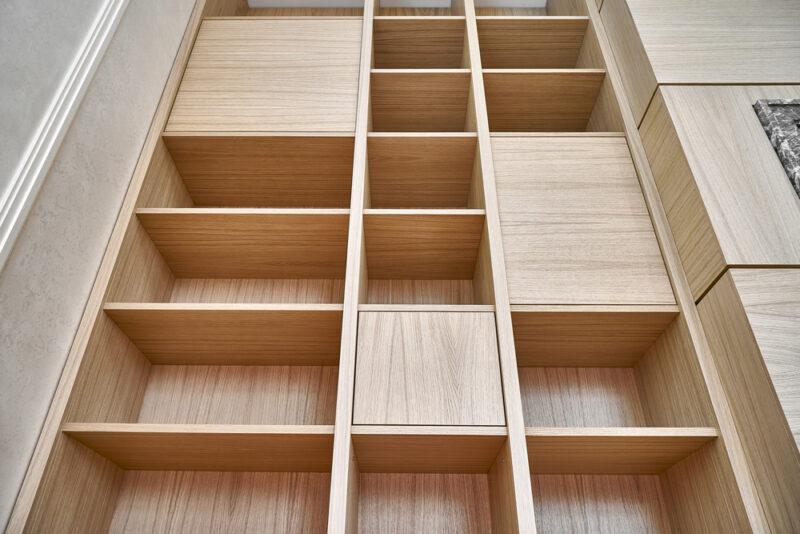

A classic use for MDF in the home is for shelving, as its strength allows it to support heavy items. Its dense texture also provides a solid foundation for screws, hooks, and mounting hardware. Additionally, MDF can be cut and shaped to fit even the most irregular spaces—perfect for homes with unconventional layouts.

MDF for Custom Creations

Beyond shelving, MDF’s consistent texture and strength make it ideal for a range of custom projects. Whether it’s crafting picture frames, storage boxes, or even wall art, MDF is a reliable option for both DIY enthusiasts and professionals alike. It’s also commonly used to repair or enhance existing furniture, such as replacing worn or broken parts of chairs, tables, or beds with cut-to-size MDF components.

Thanks to its smooth surface, MDF is easy to paint or finish, making it suitable for visible pieces like tabletops or cabinets. A custom-cut MDF board can easily replace a scratched or worn surface, giving furniture a fresh, new look without the expense of buying a brand-new piece.

The Future of MDF: New Advancements

MDF has continued to evolve with technological advancements. Today, it can be produced sustainably, often using wood waste from other processes. Innovations have also made it possible to manufacture MDF without the use of formaldehyde-based resins, offering a healthier option for home interiors.

In terms of design, moisture-resistant MDF is now available, expanding its use into kitchens and bathrooms where humidity can be an issue. Additionally, MDF can be dyed during the manufacturing process, allowing for vibrant, consistent color throughout the board—far beyond the typical brown shades. This opens up new creative possibilities, especially when combined with computerized cutting technology, allowing homeowners and designers to produce intricate shapes and designs with ease.